Although proper ring & pinion setup can be accomplished at home, I really recommend having a professional do the job. However, if a person really insists on trying it (and that is really the only way to learn), here is some information that should be helpful.

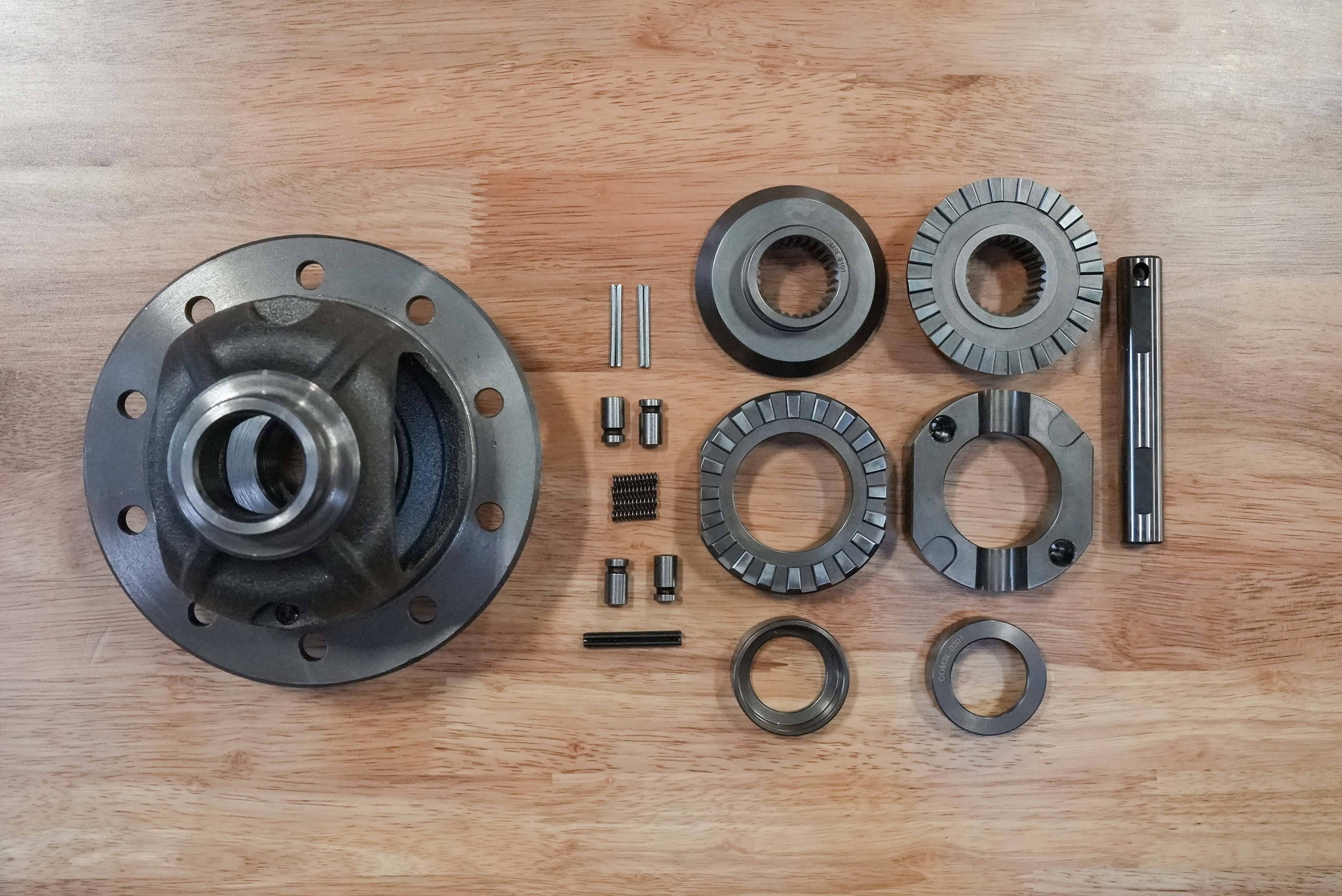

When setting up a ring & pinion, there are four critical settings that need to be correct in order to get proper setup and good gear life. They are: Pinion depth (how close the pinion is to the ring gear), backlash (how close the ring gear is to the pinion), pinion bearing preload (how much bearing drag is on the pinion bearings), and carrier bearing preload (how much bearing drag is on the carrier bearings).

Given enough time, just about any approach will work when setting up a ring & pinion. However, I suggest adjusting the four settings in the following order so that the job goes faster with less frustration.

First, set the backlash using only light carrier bearing preload. The proper preload can be added closer to final assembly. Next, check the pinion depth by way of the contact pattern. Make sure you use only real gear marking compound (available from GM as part # 1052351), as other marking substances are difficult to read. There are many theories about how to read the contact pattern, but I won’t open that can of worms now. After checking the pattern, it is usually necessary to adjust the pinion depth. After changing the pinion depth, the pattern should be rechecked. The backlash may have to be readjusted as the pinion depth is changed. It should be close to specifications in order to get a good pattern reading. Once the correct pinion depth is established, the pinion bearing preload can be adjusted.

When setting the pinion bearing preload on a crush sleeve design differential, it is always necessary to use a new crush sleeve every time the pinion nut is removed, or if the sleeve is over-crushed.

When installing the carrier, the same adjusters or shims that are used to adjust the backlash are also used to set the carrier bearing preload. Rather than trying to change the backlash and preload at the same time, I recommend getting the backlash correct and then adding preload for the final assembly. If the carrier has to be moved to set the backlash, it is easier to remove if the preload is not too tight.

Once the backlash has been set, the carrier bearing preload can be added. Some books give exact specifications of how much preload to add to the carrier bearings. I find that the given specs are not always easy to measure or achieve. If they call for 0.015″ preload, a zero point must first be established, and that is not easy either. I recommend setting the carrier bearing preload as tight as you can get it without damaging the shims during installation. For screw adjuster type differentials, I recommend about 100 to 150 ft lbs. of torque on the adjusters. From my experience, I have found it difficult to over preload the carrier bearings. I have only seen it done in a few cases, and those involved a mechanic with Schwarzenegger-like arms. Many people claim that setting the backlash too tight is good for high impact applications so that the backlash will not open up too wide. I have been guilty of this claim in the past; however, experience has shown me that it is lack of carrier bearing preload that causes the backlash to open up and not some magical transformation due to high shock loads.

Now that these four settings are correct, the installation is almost complete. Remember to use good high quality oil and follow the manufacturer’s break-in procedure

Popular Resources:

AMC

AMC

Chrysler

Chrysler

Dana

Dana

Ford

Ford

GM

GM

Isuzu

Isuzu

Nissan

Nissan

Suzuki

Suzuki

Toyota

Toyota