Do we really need to break in a new gear set? I have heard many people say “When I bought my new truck, no one ever told me to break in the ring & pinion.” Whenever we are blessed enough to afford a new vehicle, we take it easy on the engine for the first few hundred miles. While we are pampering the engine (probably for the last time ever), the ring & pinion set goes along for the ride and gets a chance to break in before we hammer the throttle.

In most stock vehicles with stock tires there is seldom a risk of a burned gear set. For those of us who modify and use our trucks, there many situations that can contribute to burned gear syndrome. Motorhomes, towing, tall tires, and high numeric gear ratios (4.56 & up) can all generate a lot of heat and cause the gear oil to break down. The greatest damage to a new gear set results from running for ten minutes or more during the first 500 miles when the oil is very hot. Any heavy use or overloading while the oil is extremely hot will cause it to break down and allow irreversible damage to the ring & pinion.

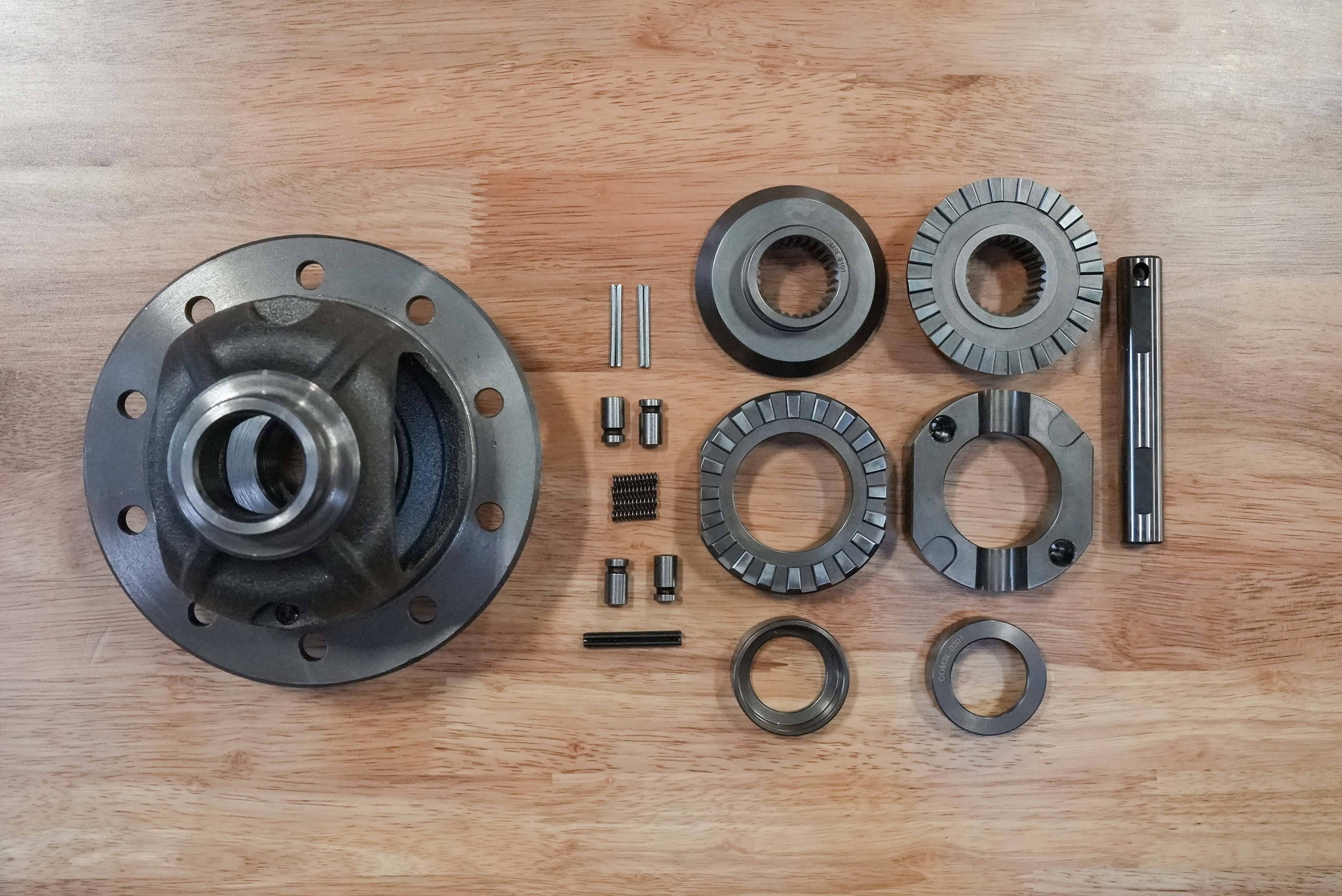

In order to make them run cooler and quieter, new gears are lapped at the factory. However, they are not lapped under the same pressures that driving creates. The loads generated while driving force any microscopic high spots on the gear teeth back into the surface of the metal. This is called “work hardening”. Work hardening is similar to forging in the way that it compresses the metal molecules into a very compact and hard formation. This can only be accomplished if the metal surfaces are lubricated and the gear temperature stays cool enough that the molecular structure does not change. If the temperature of the metal gets hot enough to change the molecular structure, it will soften the surface instead of hardening it. This may seen like a balancing act, but it all happens easily and passively as long as the oil keeps the gear cool while it is breaking in. Some of the synthetic oils on the market today can help a gear set live longer. I’ve had great success with Red Line ®, Torco ®, and Richmond Gear ® synthetic gear oils. These oils will continue to lubricate at temperatures where many crude oils break down.

Even with synthetic oils, I still recommend the following procedure for breaking in a new gear set: After driving the first 15 to 20 miles, stop and let the differential cool before proceeding. Keep the vehicle at speeds below 60 mph for the first 100 miles. I also recommend putting at least 500 miles on the new gear set before heavy use or towing. During the first 45 miles of towing, it helps to go about 15 miles at a time before stopping to let the differential cool for 15 minutes before continuing. This is necessary because not all of the gear tooth is making contact until it is heavily loaded. When towing, the teeth flex to contact completely, and cause the previously unloaded portion of the teeth to touch and work harden. It is very easy to damage the ring & pinion by overloading before the teeth are broken-in. If you take it easy on a new ring & pinion and keep it full of high quality oil, it will last a lot longer.

With regards to limited slip additives, I have found that using too much additive can lead to premature gear wear. Use just enough to keep the limited slip from chattering but not more than 4 oz for every 2 qts of oil. It is a good idea to change the gear oil after the first 500 miles in order to remove any metal particles or phosphorus coating that has come from the new gear set. This is cheap insurance and a good time to discover any problems before they grow too big.

Popular Resources:

AMC

AMC

Chrysler

Chrysler

Dana

Dana

Ford

Ford

GM

GM

Isuzu

Isuzu

Nissan

Nissan

Suzuki

Suzuki

Toyota

Toyota