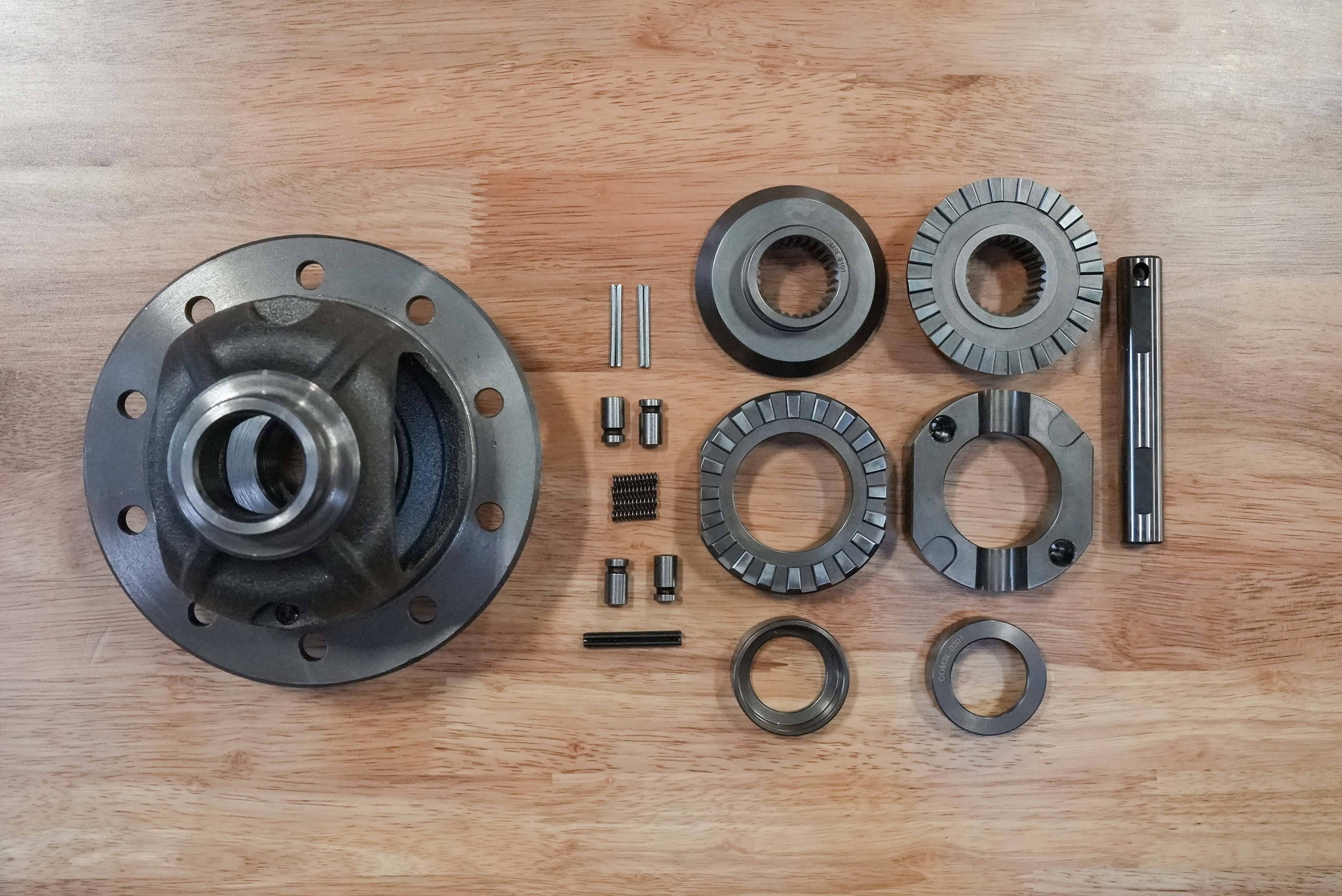

Check Your Shipment… Count Your Teeth

Before proceeding with your drivetrain project, it is essential to check your shipment to ensure that everything is in order. Conducting a thorough inspection helps identify any potential issues, verify the contents, and address any discrepancies or damage. As always, check the contents against the packing slip or order. Review the packing slip, invoice, or order confirmation to ensure all...

AMC

AMC

Chrysler

Chrysler

Dana

Dana

Ford

Ford

GM

GM

Isuzu

Isuzu

Nissan

Nissan

Suzuki

Suzuki

Toyota

Toyota