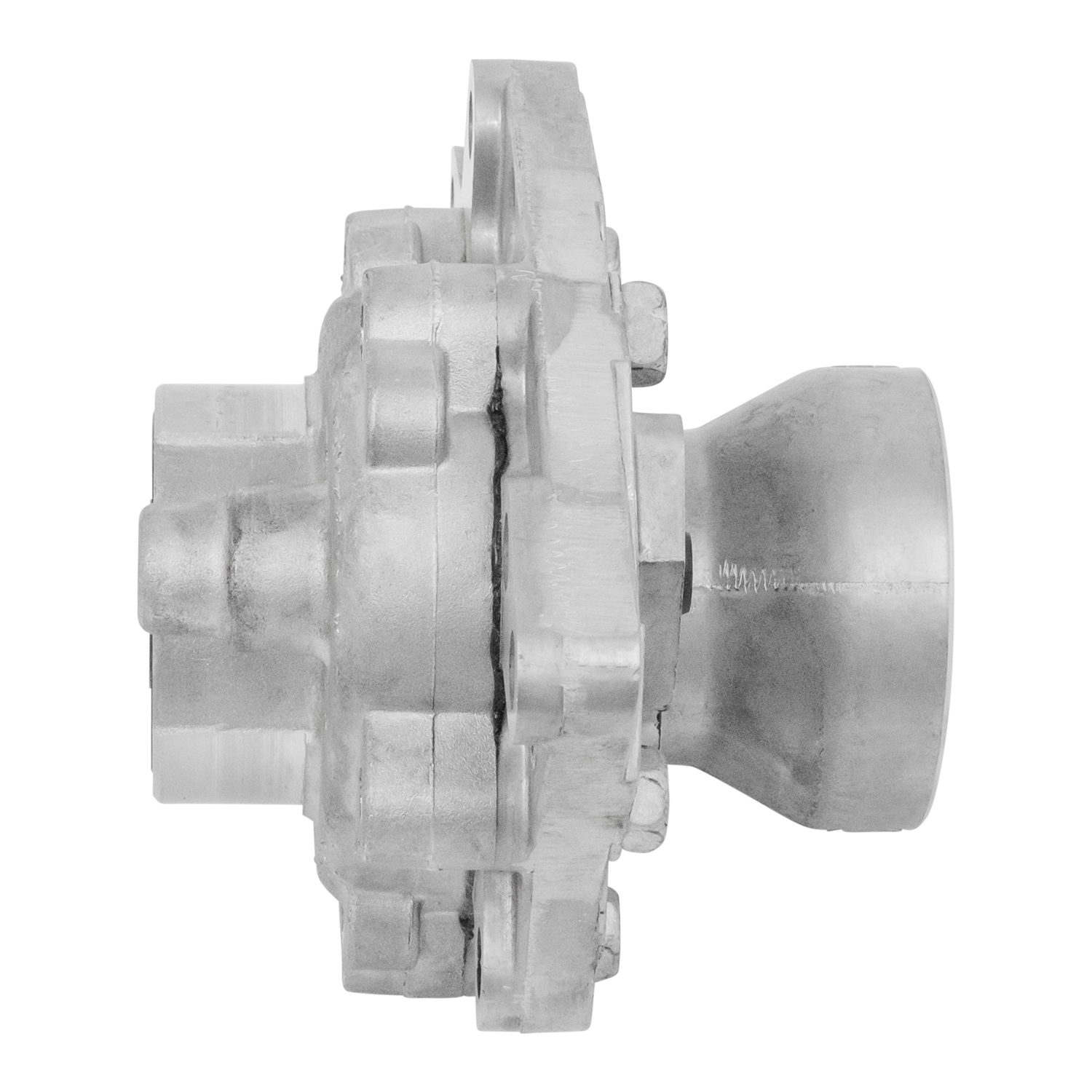

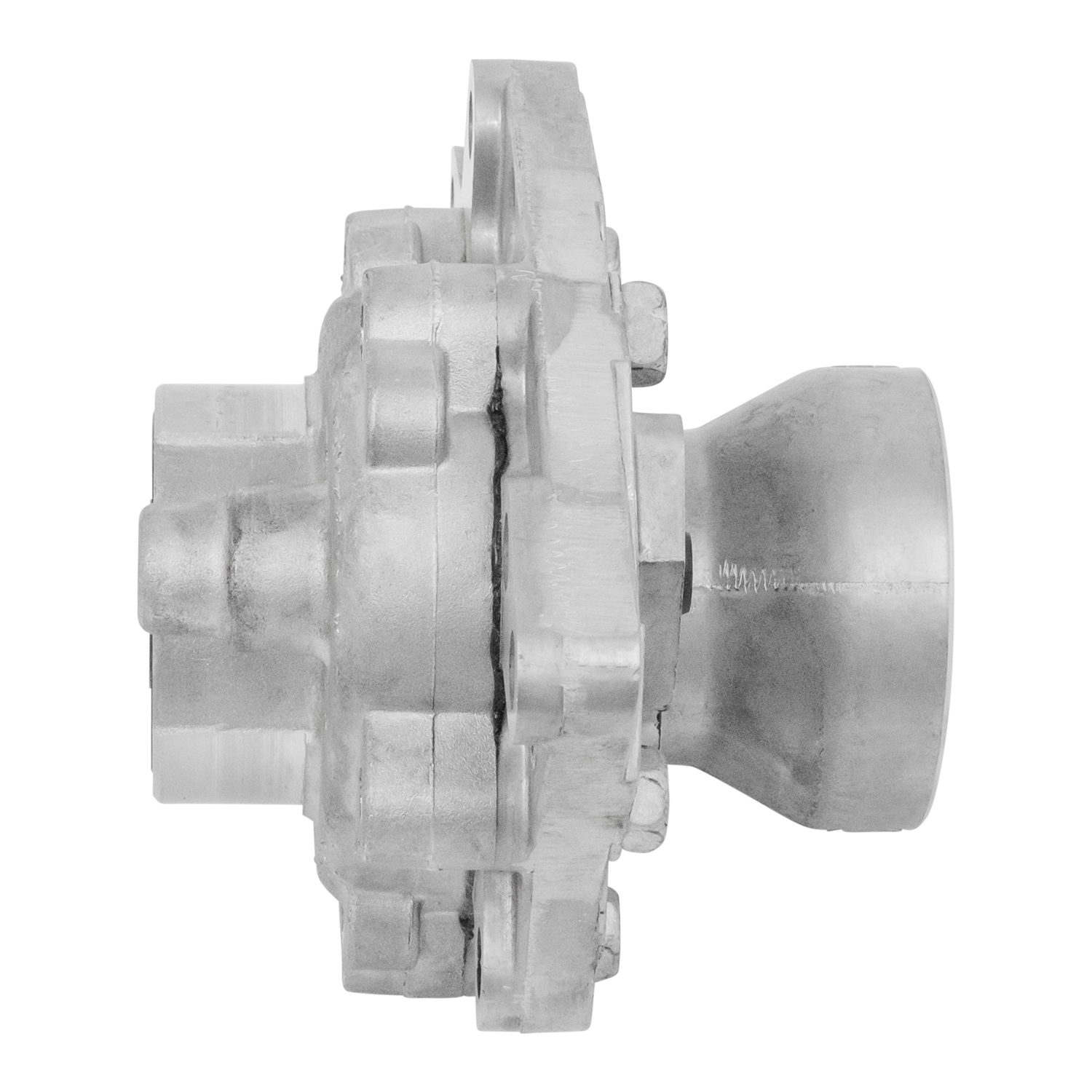

Zumbrota Drivetrain Axle Assemblies are rebuilt to the highest quality standards of precision and reliability. Each complete axle assembly is thoroughly inspected for straightness, cracks and surface wear. All internal components are fully inspected and tested including ring & pinions, internal gears, clutches and carriers. All bearings & seals are replaced. Gears are fully inspected for optimal tooth contact patterns and correct rolling torque using inch pound measurements for precise setup and longevity. Correct gear backlash is set to ensure proper gear lubrication and quiet operation. Axle tubes are inspected to ensure OEM standards of straightness. Zumbrota uses an exclusive hydro-blast rinse and sandblasting procedure on internal and external parts, followed by a proprietary shot-enticed deep cleaning, setting the standard for axle assembly remanufacturing.

Warranty information unavailable

Depends on the axle type. Semi-float and C-clip-equipped axle shafts are measured from the end of the shaft to the outer edge of the mounting flange. Axles with yokes (front axle shafts) are measured from the center of the u-joint bore to the end of the splines. Full-float designs are measured from the spline ends to the front surface of the mounting flange.

Click here for a detailed schematic of how to properly measure axles.

A semi-float axle rides on an outer bearing, thus supporting the weight of the vehicle. In semi-float applications the wheel is bolted directly to the axle. A full-float axle is a housing type in which the axle does not carry the load of the vehicle and does not have the wheel bolt directly to it. Full-float axles bolt to a spindle, which ultimately drives the wheels. They can also be removed with the wheel still on the vehicle.

Get some great insider information from our “How to Identify Your Differential & Axle Type | Differential Tech Tips” video.

How to Identify Your Differential & Axle Type | Differential Tech Tips

We predominantly use five metal types; 4320, 4340, 8620, 9310, and 1541H.

4300-series is a nickel-chromium-molybdenum alloy, i.e. chromoly, that’s low in carbon content. 4320 is used for the internals in our line of Yukon Dura Grip LSDs. We use 4340 in the manufacturing of forged gears, pinion gears, high-performance axles, Super Joints, and more. 8620 is a low-nickel alloy steel generally used in the manufacture of forged camshafts, crankshafts, and fasteners. We use it in gears and cases. 9310 is an alloy steel with more nickel and chromium than 8620. 9310 can better endure high shock loads without failing and we use it in Spartan Lockers. 1541H is a high-grade carbon steel used in our replacement axles and u-joints, and similar products. A caveat here, heat-treating plays a definitive role in a given alloy’s hardness and other properties that impact their performance in automotive drivetrain applications. We use advanced heat-treating techniques to fine tune our alloys to their intended usage.