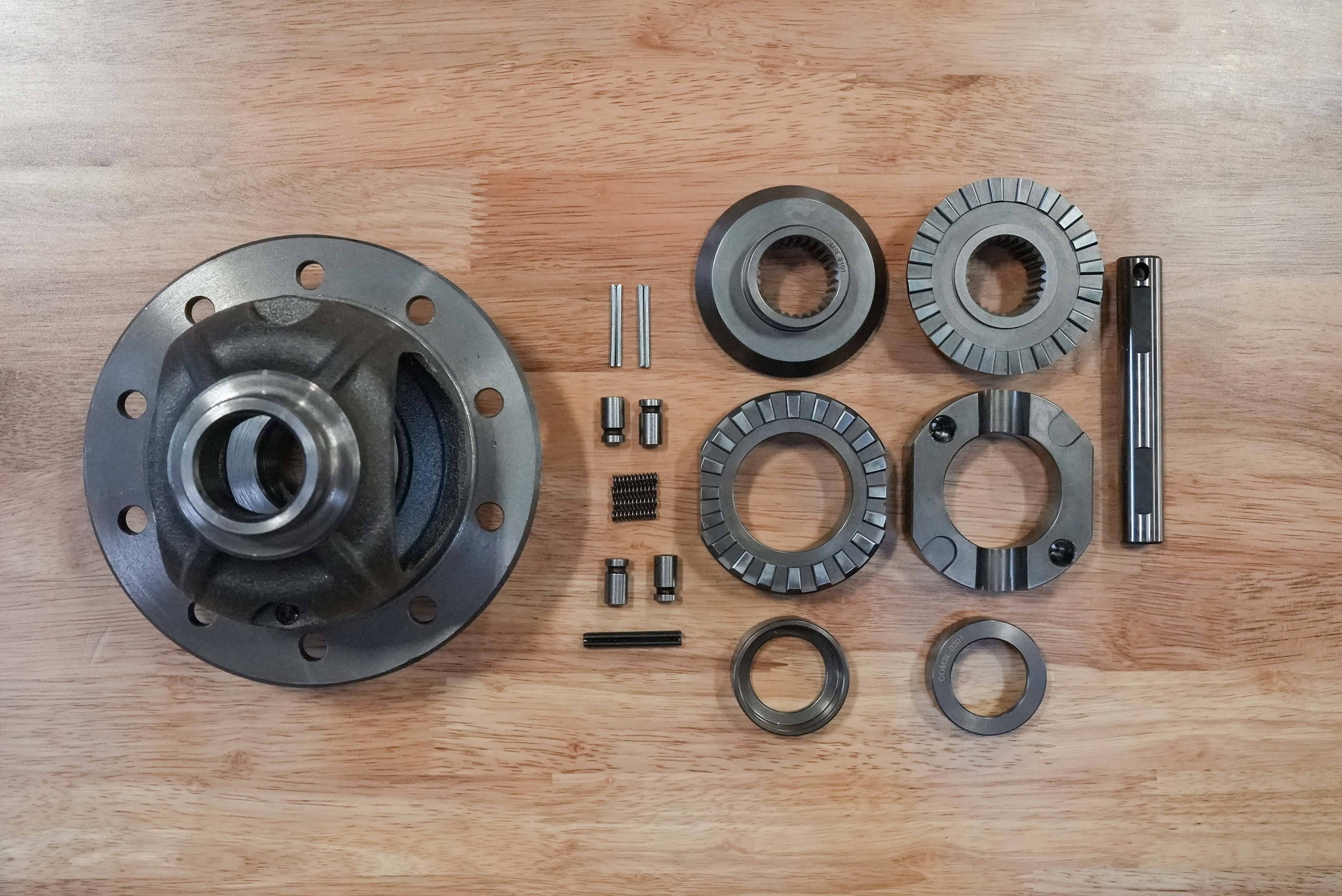

Setting up a differential involves a lot of measuring, disassembly, reassembly, adjusting, and re-measuring. Aside from the tools needed to assemble and disassemble a differential, a good mechanic needs the right tools for making accurate measurements. Having the right tools makes the job far easier, while the wrong tools can make the job miserable, if not impossible.

When working on a differential you will need a wide variety of special tools. If you do not have the tools you need, they can often be rented or borrowed. If you want to learn to build differentials or plan on building them on a regular basis, then investing in good tools is definitely worth the money.

Using the correct tools, such as the ones listed below, will not only save you time but also prevent parts from being damaged.

- Dial indicator

- Genuine gear marking compound and a clean brush

- Calipers or a micrometer

- Bearing puller

- Bearing press (or access to one)

- Three foot long breaker bar or strong impact gun

- Pinion nut socket

- Six point cross pin bolt wrench

- Pry bars for removing the carrier case

- 48 oz plastic dead blow hammer

- Assorted brass punches

- Center punch or number stamp for marking main caps

- Foot pounds torque wrench

- Inch pounds torque wrench

A good bearing puller is needed when removing the carrier bearings, and especially when the carrier shims are located between the side bearings and the carrier case. There is not any way to consistently set the backlash correctly without a good dial indicator. Gear marking compound is sometimes difficult to find, but always worth finding. Dial calipers can be found on many tool trucks and hardware stores. A good inch pound torque wrench is an expensive investment for a single installation, but it is worth finding. A foot pound torque wrench CAN’T be used for setting the pinion bearing preload as it is not accurate at settings that low.

There are some tools that are not absolutely necessary. Bearing race drivers, for example, are not really necessary. A good bronze bunch (about 7/8″ dia x 12″ long) works well for driving bearing races in and out. Just be careful to remove any chips prior to assembly. Old inner and outer bearing races can be used for driving in seals and guiding on bearings during press operations. An old cross pin shaft can be ground to a point on one end and used for driving out the pinion shaft without damaging the threads.

It is very important to accurately measure backlash, pinion bearing preload, and bolt torque. If any of these adjustments or torques are not correct, it could lead to early parts failure.

Now that you are ready to dig in and build your own differential, remember that using the right tools will save you damaged parts, as well as time and frustration.

Popular Resources:

AMC

AMC

Chrysler

Chrysler

Dana

Dana

Ford

Ford

GM

GM

Isuzu

Isuzu

Nissan

Nissan

Suzuki

Suzuki

Toyota

Toyota