I have had more than a few customers come back to our service shop after a gear ratio change to complain that we caused a new vibration in their vehicle. In actuality, we inadvertently caused the vibration by increasing the driveline speed.

When changing to a lower gear ratio (numerically higher) the driveline speed increases proportionally to the change in the ratio. For example, when changing the ratio from 3.08 to 4.56 there is a 48% change in the ratio and a 48% increase in driveline speed. This means that a vibration that would have been noticeable at about 90 mph is now noticeable at 60 mph. This higher driveline speed makes the vibration more noticeable because while it previously existed at 90 mph, it may have gone unnoticed due to the amount of vehicle vibrations it had to overcome in order to be noticed. If the customer installed taller tires and raised the vehicle before changing the gear ratio, the vibration is probably caused by the lift. This vibration caused by the lift and wrong driveline angles would not be noticeable until the new ratio was installed, since the tall tires and stock ratio kept the driveline speeds too slow for the vibrations to be felt. Vibrations due to wrong angles are usually easy to identify because they are harmonic or cyclic. This means that the vibration varies in pitch or intensity even when traveling at a steady speed. The results is a “whir … whir … whir” type of noise.

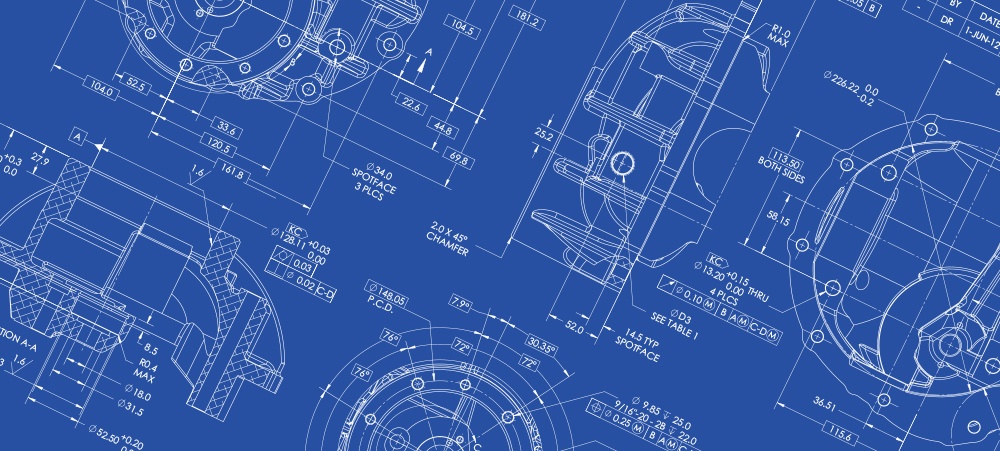

The solution to wrong angles is easy in theory, but not always easy in practice. There have been many good technical papers written on this subject, so I won’t go into detail now. I will however cover a few of the basics. In order for a two U-joint driveline to be free of vibration it must be in balance, and the angle of the front U-joint must be the same as, or very close to, the angle of the rear U-joint. If there is a noticeable difference in the angles, there will be a vibration.

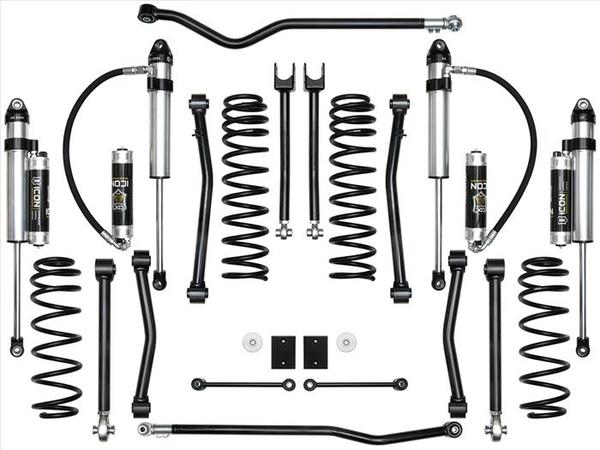

If it is not possible to match the front and rear angles, a constant-velocity joint can be used at the transfer case end with no angle in the U-joint on the differential end. Although it is expensive, and only works if the pinion is not offset side-to-side from the output shaft, this is the only cure in many lift situations. I have seen vehicles use a constant-velocity joint at each end of the driveline. This is more expensive but will fix any angle problem. Another solution is to rotate the differential pinion angle up or down to match the front angle. This is usually not easy and can be accomplished with wedges, by moving the spring pads, or by rotating the axles tubes in relation to the differential center section. For some vehicles there are aftermarket kits available for lowering the transfer case or installing adjustable length control arms. Although these may seem like extreme measures, they are sometimes the only way to eliminate or lessen vibrations.

Note: If the vehicle has a differential pinion offset to the side from the center of the output shaft on the transmission or transfer case, the angles due to this offset will not cause vibration. This is because the pinion shaft and the output shaft are still parallel with respect to these side-to-side angles.

I have seen some lifted vehicles that vibrate no matter how much care is taken to balance the driveline and match the angles. It is one of the things that we sometimes have to live with in order to have a lifted vehicle.

Popular Resources:

AMC

AMC

Chrysler

Chrysler

Dana

Dana

Ford

Ford

GM

GM

Isuzu

Isuzu

Nissan

Nissan

Suzuki

Suzuki

Toyota

Toyota