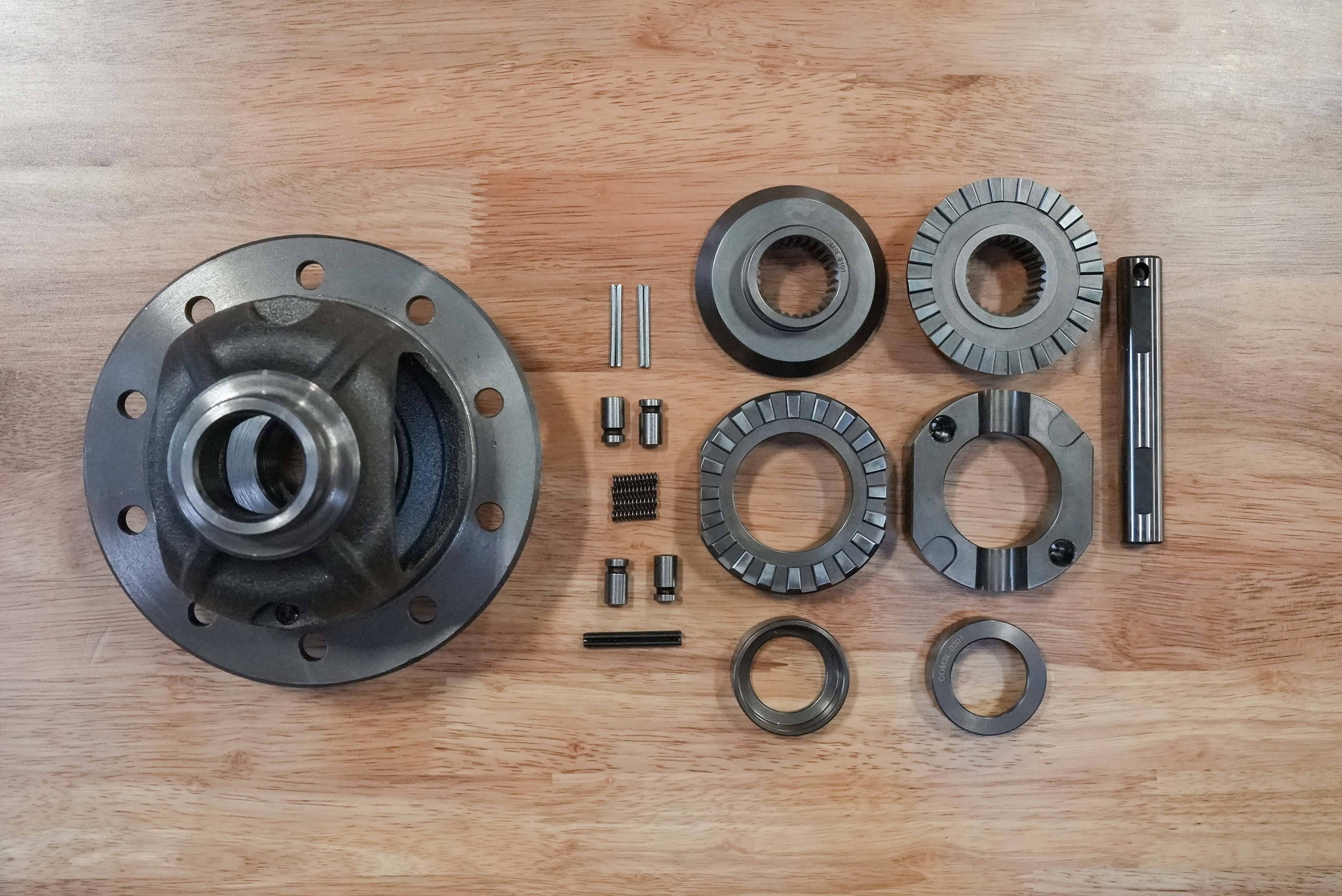

When changing the gear ratio for more power or more speed, sometimes a new ratio requires a different height carrier case. Carrier height changes are commonly referred to as a “carrier break”, although this doesn’t have anything to do with broken parts. What it does refer to is the difference in the ring gear mounting height on the carrier case itself or a breaking point from one height to another.

When the gear ratio is changed, it is accomplished by changing the number of the ring gear teeth and / or the pinion gear teeth. The gear ratio is determined by dividing the number of teeth on the ring gear by the number of teeth on the pinion gear. For example, 41 divided by 10, which equals 4.10 for a gear set with 41 ring gear teeth and 10 pinion teeth. As the ratio increases numerically, the ring gear usually stays the same diameter which requires that the pinion gear diameter gets smaller. The smaller pinion gear will not reach the ring gear unless the ring gear is made thicker or the carrier case mounting flange is moved closer to the smaller pinion gear. The ring gear material is very expensive and it is far cheaper (especially when building millions of rear ends for production) to change the position of the carrier flange. Changing the flange height usually requires very little or no extra material on the carrier case.

An example of a popular rear end that has a carrier break is the Dana Spicer model 44. The D44 uses two different height carriers. When using ratios that are 3.73 or numerically lower (such as 3.54 or 3.07) a short carrier case is used to allow the large pinion gear to fit in the housing and move the carrier flange far enough away for the ring gear to have thickness left to support teeth. When using ratios that are 3.92 or numerically higher (4.09 all the way to 5.89), a taller carrier case is used to move the ring gear closer to the small pinion, without having to use an excess of expensive ring gear material.

In order to avoid the expense of a new carrier case, some people use ring gear spacers. A spacer is a quick fix, but from my experience, not a good idea. If the spacer pushes the ring gear up off of the pilot surface that centers it on the carrier, it will have to rely on the ring gear bolts to hold it centered. The ring gear bolts are neither strong enough or accurate enough to center the ring gear correctly. This in turn causes the ring gear to “walk” around on the carrier and the tooth contact will suffer. Before you know it, the gear set will be noisy, wear out, orbreak. I have seen a very few cases where the ring gear pilot surface on the carrier is large enough that it could still touch the ring gear when using a spacer. This is somewhat better than no contact, but the bolts will still be overloaded and the unit will not last.

If your ratio change calls for a different height carrier case,there are a few options that will work just fine. Thick ring gear ring & pinion sets are available for many popular applications. The thicker gears have absolutely no side effects. The thicker ring gear has lots of material exposed to the oil so it runs just as cool as a thin gear set. Not only has the aftermarket used thick ring gear sets for many years, many original equipment vehicles have used thick ring gear sets or offered thick gear set options. For example, Ford does not use any carrier breaks on any of their corporate rear ends which means that many of their gear sets could be considered “thick”.

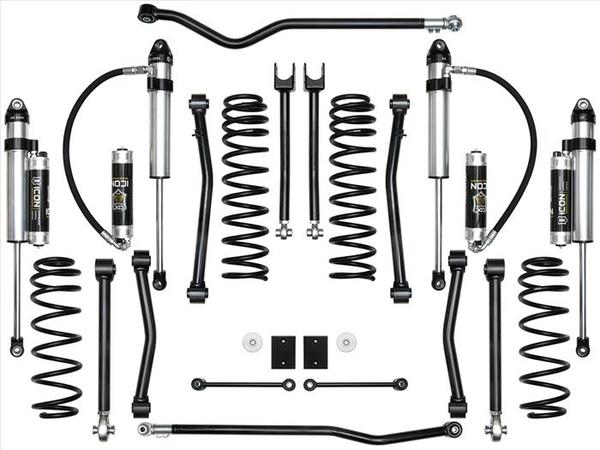

The other option that will solve the problem of dealing with a carrier break is the obvious. Buy a new carrier. This may sound expensive and in some cases it is. In many cases the carrier case is less than $100. Or, it may be a good time to upgrade to a positraction or locker. Replacing the carrier with a posi or locker allows you to upgrade and get the appropriate carrier at the same time.

Next month will include a list of carrier brakes for popular truck, passenger car, and Jeep rear ends.

Popular Resources:

AMC

AMC

Chrysler

Chrysler

Dana

Dana

Ford

Ford

GM

GM

Isuzu

Isuzu

Nissan

Nissan

Suzuki

Suzuki

Toyota

Toyota