We get a lot of questions asking how much it should cost to have a rearend setup. Unfortunately, the answer is never simple, due to all the variables involved. The hourly rate a shop charges can vary from as little as $60 to over $200 per hour. Labor charges may depend on location, competence, warranty, overhead, and the individual shop or mechanic’s desire to work on differentials. Access to a flat rate book that provides standard hours required to do the job can be helpful.

Ultimately, the shop is going to charge whatever they feel is fair, and we have found the flat rate books to be misleading at times. The guidelines we are about to present are only provided to help the reader in their search for a fair deal and should not be taken as gospel. If someone wants to charge more, and you want to have them do the work, then the only solution is to pay the price. However, if you feel that an equally good job can be done elsewhere, then so be it. Always consider the cost to be secondary to the quality of the work you receive.

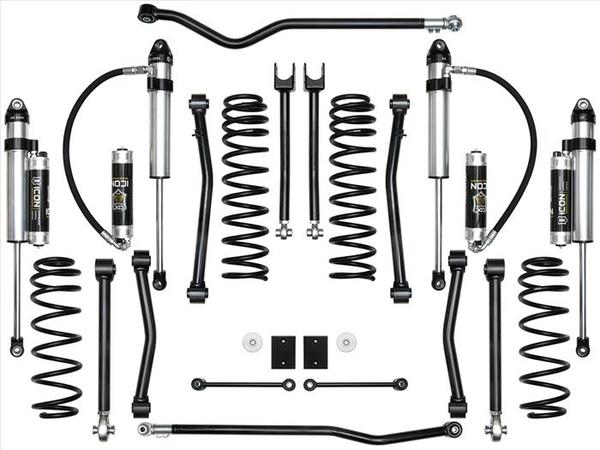

The following rates are per axle for most passenger cars, Jeeps, mini trucks, and half ton trucks, if the vehicle is driven to the shop:

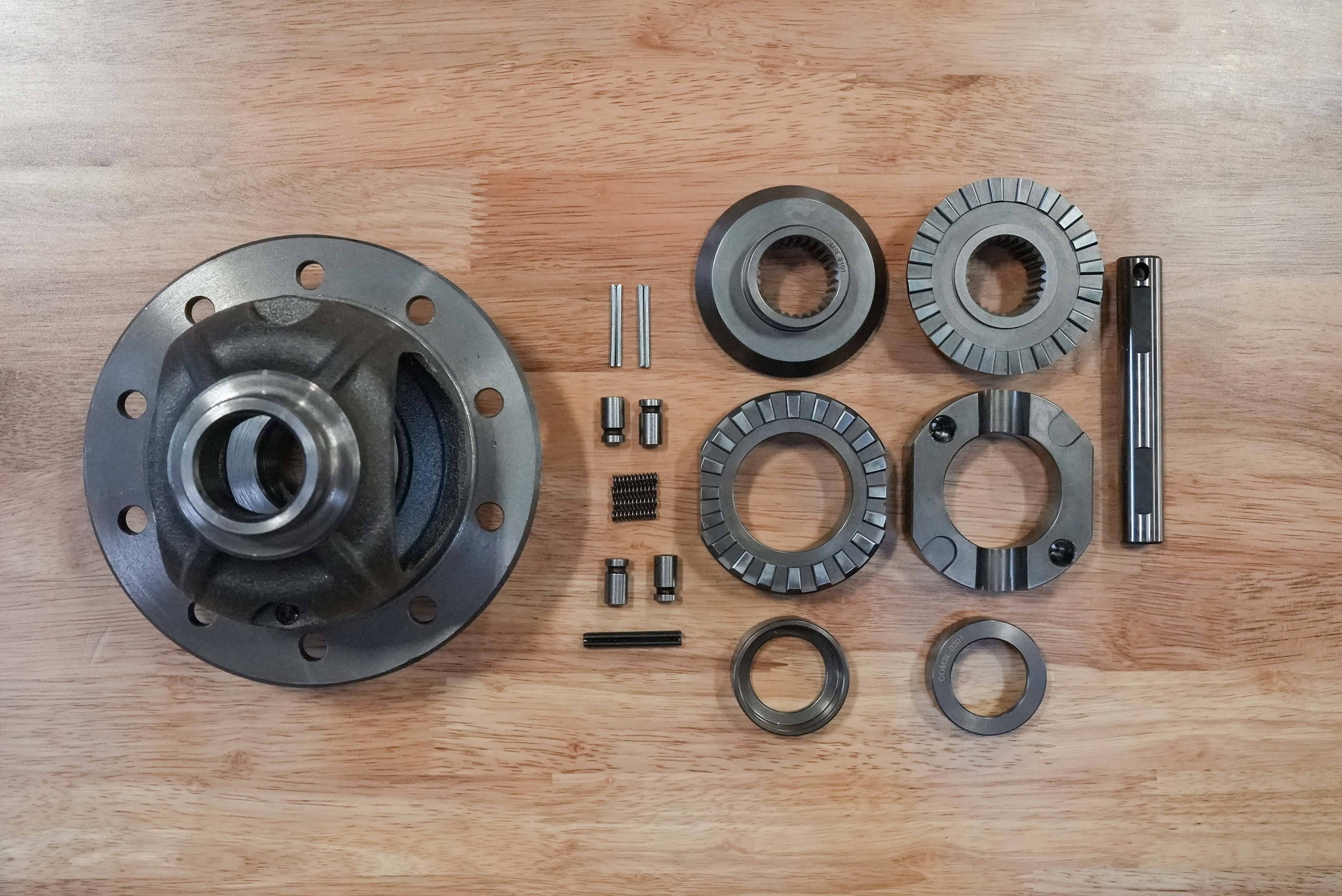

- Rebuild with new bearings and seals using same ring & pinion: 4 to 6 hrs.

- Install ring & pinion, and bearings and seals if needed: 5 to 7 hrs.

- Install limited slip or locker, without removing pinion: 3 to 4 hrs.

- This list of variations or exceptions to the above rule are a few of the common things that make the job more difficult, or easier, and require an adjustment to the cost:

- Differential is brought in out of the vehicle: Subtract 1.5 hrs.

- Three quarter and one ton trucks: Add 1 hrs.

- General Motors independent front suspension: Add 3 to 4 hrs.

- Late model independent front suspension (excl GM): Add 1 to 4 hrs.

- Two-piece tapered axles: Add 1.5 hrs.

- Motorhomes or large Box Vans that do not fit on common lift: Add 4 to 8 hrs.

Another thing to be aware of when shopping around is warranty. Any shop that is familiar with differentials will probably have some limitations to their warranty. Some of the common warranty restrictions that we use in our shop are: mini and mid-size trucks (Jeeps, Ford Rangers with 7.5″ diff, Toyota trucks) with tires taller than 31″; half ton trucks with tires taller than 33″; three quarter and one ton trucks with tires taller than 35″; trucks used for towing have a shorter than standard warranty; and vehicles used for competition or racing are not warranted. These may seem like extreme limitations, but they are sometimes necessary to protect the shop from people who abuse their vehicles on or off road.

If you purchase parts directly from the shop doing the work, expect to pay a little more. Every shop has the right to make a profit when stocking or handling parts. And shops can be very helpful if there’s ever any warranty issues related to the parts. Use your best judgment and remember that supply and demand always hold true when it comes to quality parts and service.

Popular Resources:

AMC

AMC

Chrysler

Chrysler

Dana

Dana

Ford

Ford

GM

GM

Isuzu

Isuzu

Nissan

Nissan

Suzuki

Suzuki

Toyota

Toyota